- General purpose

- Functional

- Special type

- Other knives

- grinding tools

- Other tools

- High frequency sintering machine

Home / Production Process

LV International imports high-quality tungsten steel rods from Germany and Japan and cuts them to specified lengths according to customer needs.

Before carrying out the grinding operation of the forming milling cutter, it is necessary to process semi-finished products such as spherical shape, step difference, effective length and so on according to the situation.

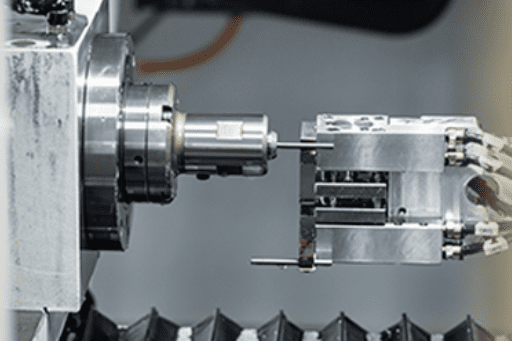

LV International uses MAKINO SEIKI's fully automated CNC grinding machine to grind tools to achieve high efficiency and precision.

In order to ensure quality, LV International performs coating processing in-house by itself, provides a variety of coating options according to the different needs of customers, and provides the most complete services.

LV International deeply realizes that "only high-quality products can meet customer expectations"! Therefore, it uses German-made ZOLLER tool measuring instruments and professional inspectors implement a strict quality control system to ensure the quality of each milling cutter. perfect quality.

After passing the quality inspection, the milling cutters will be laser-engraved with LV International's trademark, model and specifications on the tool handle, put into the tool box and attached with a sticker. It is our consistent insistence to provide the best products to our customers. .

© LV INTERNATIONAL CO., LTD. All Right Reserved.